Manufacturer of Can Filling And Seaming Machine - Vacuum Seamer – Excellent Company

Manufacturer of Can Filling And Seaming Machine - Vacuum Seamer – Excellent Company Detail:

This Vacuum Seamer is suitable for the double seaming of cans to be vacuum-sealed with function of steam jet.

The seamer machine is constantly and automatically running with filled cans and lids through a process with mechanism to fit each can with lid covered. An automatic system controls and keeps constant the steam jet for each can at the moment of seaming.

The cans used for this process can be made of cardboard, aluminium, plastic, tinplate, etc. with easy open lid, standard lid( normal lid), peel off lid. The stacked lids are divided one by one by a screw and are then fed when the seaming tray raises the can and the lid cover the cans. At this process cans and lids will be seamed automatically.

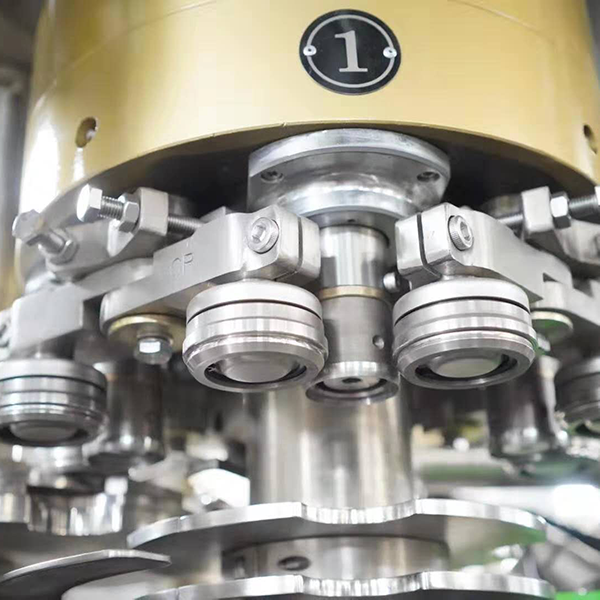

The seaming process consists of two phases: in the first operation, container hook and cover hook combined and bennded preparing for seacond operation. While in the second operation, containers and covers are hermetically sealed.

MAIN FEATURES

The machine is constructed with strong stainless steel and its critical points are made of special stainless steel materials resistant to corrosion.

An advanced and automatic lubrication plant, equipped with oil recirculation device (specific for food),is installed on the machine. This machine is equipped with steam ejection device and condensation ejection system.

The machine moving parts and seaming roller and chuck are installed . The moving parts are constantly oiled to make sure that the parts on the machine running efficiently and keep parts in good performance. The can and lid feeding system is electronically synchronized to guarantee their perfect synchronization. The machine equiped a continuous water drainage system that collects the water during the vacuum-sealing process. This seamer is also possible to use as vacuum seamer when add vacuum barrel and vacuum pump to work with canning wiIt is also possible to use the Vacuum Seamer as normal Seamer to work with hot preserving liquid.

SERVICE

We provide whole line canned food solution

Technical service on canned food production at process on pre-production – Filling – Seaming – Sterilization – Drying – Labeling

OPTIONAL

Kernel Filling Machine

Empty Container Depalletizing Machine

Autoclave

Can Drying Machine

Labeling Machine

Product detail pictures:

Related Product Guide:

We stick to our enterprise spirit of "Quality, Performance, Innovation and Integrity". We purpose to create a lot more price for our prospects with our rich resources, innovative machinery, experienced workers and great products and services for Manufacturer of Can Filling And Seaming Machine - Vacuum Seamer – Excellent Company, The product will supply to all over the world, such as: Provence, Seattle, Greece, To create more creative products, maintain high-quality products and update not only our products but ourselves so as to keep us ahead of the world, and the last but most vital one: to make every client satisfied with everything we offer and to grow stronger together. To be the real winner, starts here!

Zhangzhou Excellent ,with more than 10 years in import and export business, integrating all aspects of resource and being based on more than 30 year experience in food manufacturing, we supply not only healthy and safe food products, but also products related to food – food package.

At Excellent Company, We aim for excellence in everything we do. With our philosophy honest,trust, muti-benefit, win-win, We have been built up strong and lasting relationships with our clients .

Our objective is to exceed our consumers’ expectations. That is why we strive to continue to provide clients with high quality products, best before-service and after-service for each one of our products.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!